|

A Guide to Implementing the Theory of

Constraints (TOC) |

|||||

|

Local Safety In this discussion we will follow the general

argument of Umble and Srikanth (1, 2).

We will assume a “perfect” operation, one with just process time and

queue time or safety time. The

objective is to show how rolling up local safety into global safety makes the

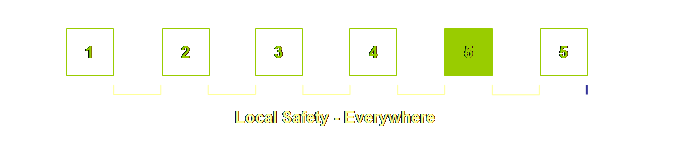

whole operation safer and potentially more economical as well. Below we have simple process of 6 sequential

operations separated by local safety time buffers. Operations and buffers are drawn in

proportion to the time taken; we will assume each operation takes five hours. Therefore actual processing time is 6 steps

of 5 hours duration. The safety time

between each operation is also 5 hours.

Therefore total lead time is 6 by 5 plus 5 by 5 = 55 hours. We can, in this simple example, quote to

our client a delivery time of 55 hours after starting the job. The blue marker represents the delivery due

date. The 5th operation is a

constraint.

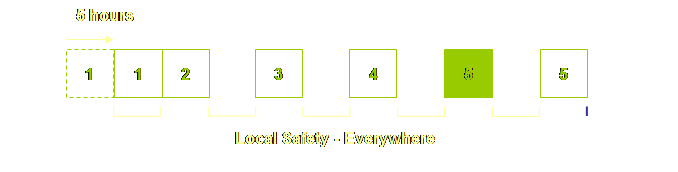

One moment – operation 5 started 10 hours late. Operation 5 is our constraint! That means our constraint stood idle for

some time. We lost output – we didn’t

lose operating expense unfortunately.

So throughput went down, and we started shipping late. The local safety buffers failed to protect

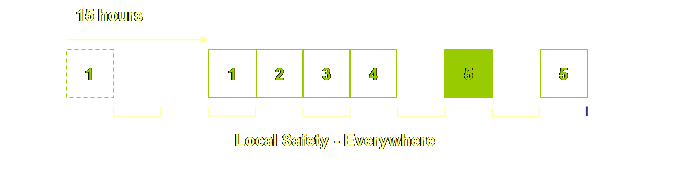

us from this disruption originating deeper in the system. Let’s rearrange the existing local safety then to

better protect the constraint. All the

local safety before the constraint is “rolled-up” into a global safety buffer

in front of the constraint.

A major people issue is to have local workers and

management understand the power of global safety and then to get them to

relinquish their local safety and adopt global safety – and then once

global safety is in place to make sure that it is not harmed by other

erroneous policies. Generally these

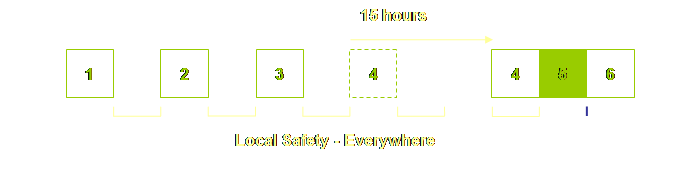

issues become one of “fear of losing control.” Creating global safety is an exploitation step,

reducing the amount of total safety as a consequence is a subordination

step. We aggregate and subordinate our

local safety everywhere to a small number of more effective global safety

buffers located exactly where it is needed – in front of any constraints,

control points or assembly points, and at shipping. To return

to the previous page press Alt key + left arrow. (1) Umble, M., and Srikanth, M. L, (1996)

Synchronous manufacturing: principles for world-class excellence. Spectrum Publishing, pp 139-144. (2) Srikanth, M. L., and Umble, M., (1997)

Synchronous management: profit-based manufacturing for the 21st

century. Volume One. Spectrum Publishing, pp 195-201. This Webpage Copyright © 2003-2009 by Dr K. J. Youngman |